PCB

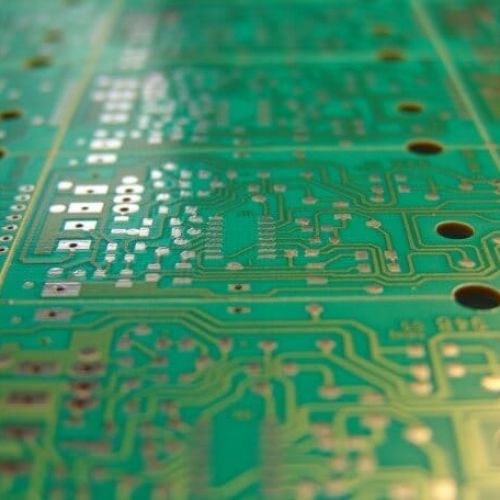

PCBs in the production of white goods have a long tradition. Today, we can’t imagine any appliance in the kitchen or bathroom without having at least one printed circuit board. The PCB enables the operation of the on / off switch, temperature setting, enables light signals, regulates the water level, heating…

Our printed circuit boards can be found in various household appliances: refrigerator, washing machine, dishwasher, small household appliances, stoves, ovens and more other.

The white goods industry is a mature industry, intertwined with strong competition and globalisation. The main white goods products are divided into several groups: washing and drying technology, refrigeration technology, dishwashing technology, cooking technology and small household appliances.

Like the entire world economy, white goods have undergone drastic changes in recent years. With technological development and new concepts of marketing and production, competition has greatly intensified and globalisation has increased. Manufacturers adapt to difficult market conditions by managing the supply chain and economies of scale.

The development of white goods in the future will be influenced by several factors, such as new materials, new technologies, high raw material prices, increasing pressures of ecological trends, the demographic structure of the population and their consumer culture. In recent years (especially during the epidemic), people have been placing increasing emphasis on decorating and furnishing their homes, which means that household appliances are becoming part of the visible living space, which represents an opportunity for modern design of white goods.

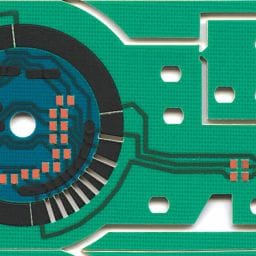

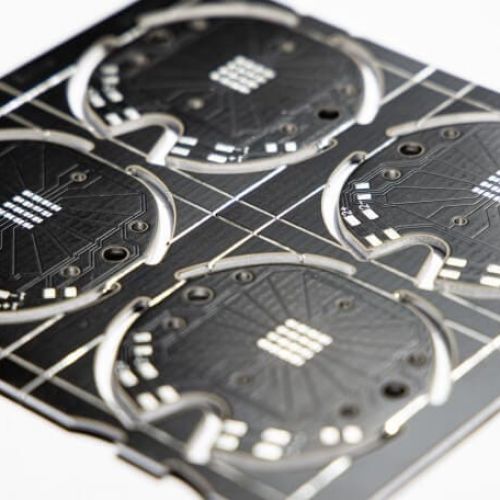

PCB for IR heaters

With our knowledge and experience, we have contributed to the development of a high-tech product suitable for every home and office. IR heating panel is environmentally friendly and low energy consuming.

Printed circuit boards are mainly manufactured for LED lighting technology, household appliances, automotive electronics, telecommunications, medical equipment and other technologies.

AKA PCB has three production lines designed for serial production and one dedicated line for express PCB service and quick samples production.

We can process standard panel size 533mm x 610mm, and also double 610mm x 1200mm sheet size.

We process PCB from standard materials in stock:

- FR4 CTI600V

- CEM3 CTI600V

- CEM3 High Thermal CTI600V

- CEM1 CTI600V

- IMS

- special materials.

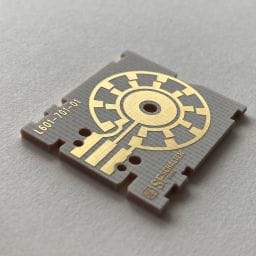

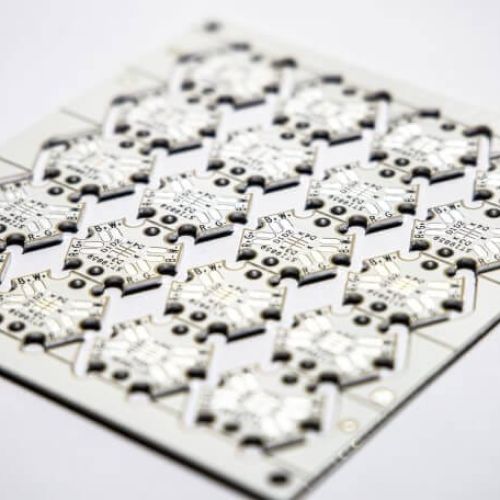

IMS PCBs are used primarily as heat sinks for high power LEDs and other power components.

AKA PCB has three production lines designed for serial production and one dedicated line for express PCB service and quick samples production.

No prepreg type materials:

- 5052 Aluminum Alloy

- Isolation layer 6KV EBD

- Isolation type 2W/MK and above

- Rigid or flex type

- Circuit layer copper thickness 35µm-210µm

- IMS Thermal conductivity 1-9WmK

- CNC or punching processed

- White, black, green or white high reflective solder resists available.

Printed circuit boards mainly used for LED lighting applications (led engines, strips and other applications).

AKA PCB has three production lines designed for serial production and one dedicated line for express PCB service and quick samples production.

We can produce from standard formats to extra-long strips (1200mm x 600mm).

We have in stock all standard PCB LED Engine CCL (copper clad laminates):

- FR4 CTI600V

- CEM3 CTI600V

- CEM3 High Thermal CTI600V

- CEM1 CTI600V

- special materials.

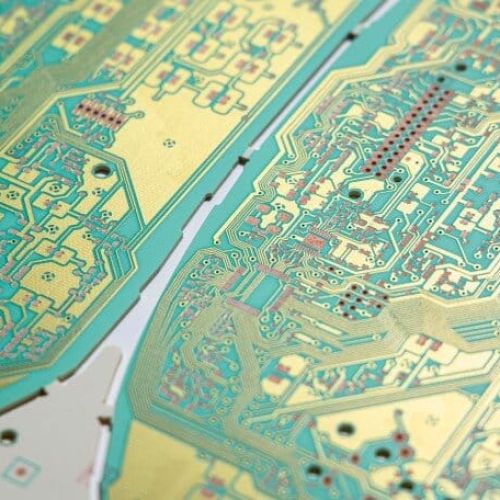

Heavy copper printed circuit boards are designed to use where very high electrical curents are present on board, or in order to dissipate heat away from components.

Printed circuit boards are specially designed for Solar Panels, Power supplies, Automotive industry, power converters and the military.

AKA PCB has three production lines designed for serial production and one dedicated line for express PCB service and quick samples production.

Including:

- FR4 base

- Aluminum base

- Copper base

- Warm white

- Cold white

- High reflection white

- Black

- Green

- Exposure process for quick supply and high-resolution projects

- Screen print process for high volume low-cost production

- THERMAL INTERFACE PASTE

- ADHESIVE RESISTANT TO SOLDER PROCESS TEMPERATURE

- SURFACE FINISH – OSP (Organic solder Passivation), HAL (Hot air levelling lead free), ENIG (electroless Nickel immersion Gold)