Because we continuously upgrade our process, our production is lean and fast. Take a look into our process.

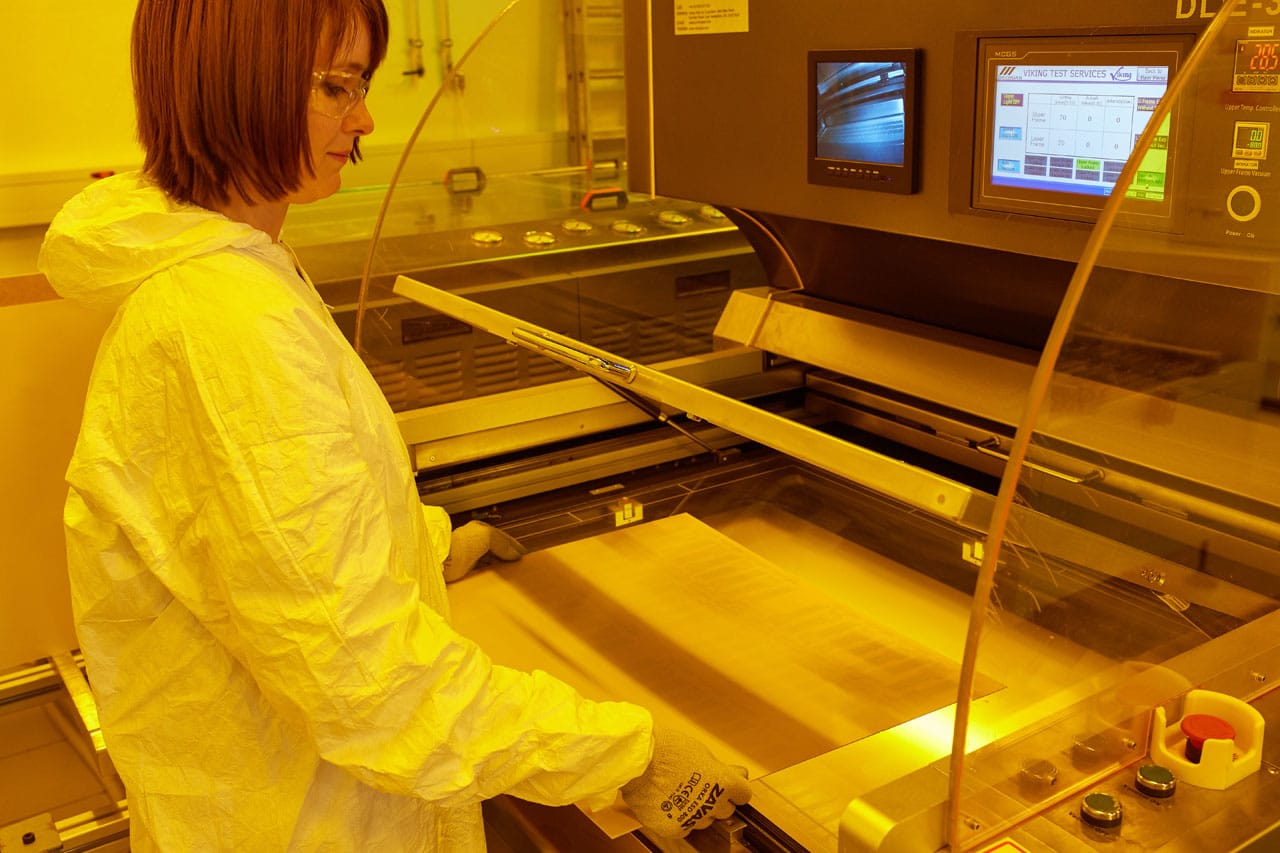

Production is fully supported by CAD-CAM technology and compatible with CAD systems for the construction of printed circuit boards via GERBER or DXF format.

We accept different data file formats: Gerber RS274-X, ODB++, HPGL, IPC, Eagle, DXF,….

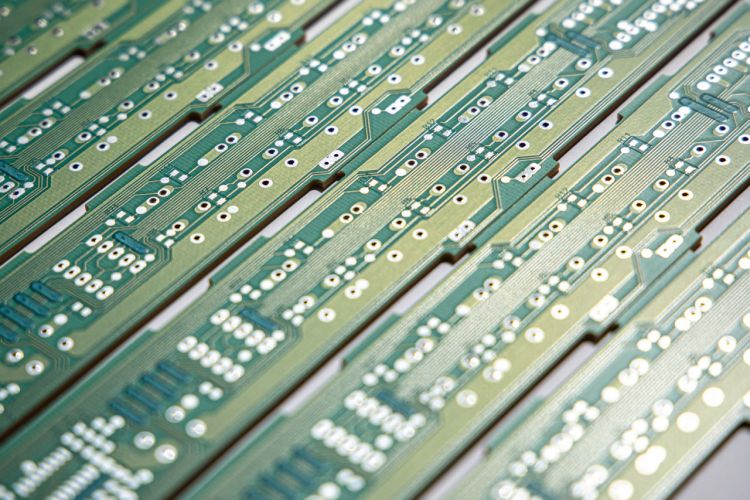

Computerised management of material stocks enables us to manipulate transparently and accurately. The process of making a printed circuit board begins with cutting the base material – CCL copper clad laminate.

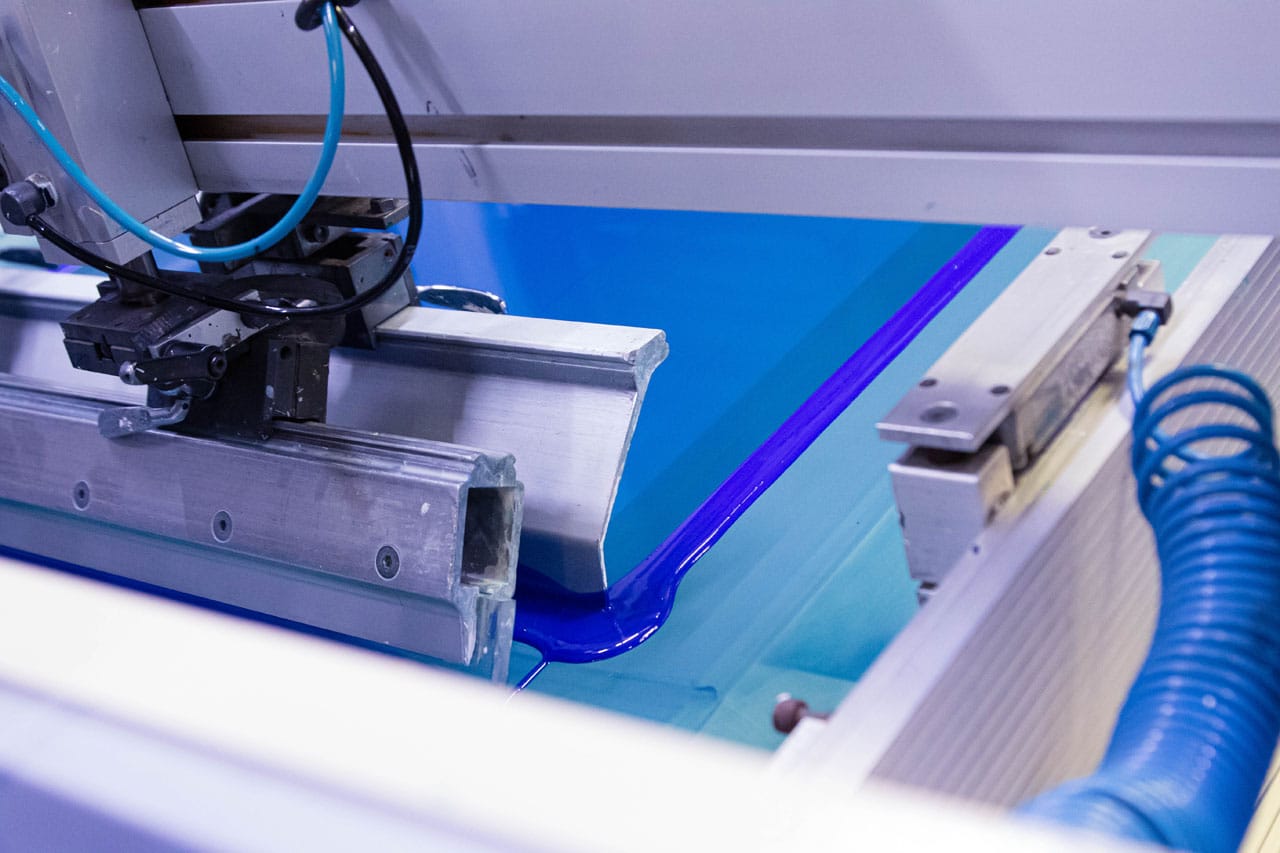

By using a patented automatic chemical controller, we precisely control all of the etching parameters. This represents the basis for quality etched copper patterns, especially for fineline PCB products and thick copper foil cladded PCB.

We also take care of the environment with a new automated water treatment system. All waste waters after treatment are below EU regulated limitation and are regularly measured and recorded.

Our own tool shop enables very efficient and flexible production of tools for mass production of printed circuit boards.

The most technologically advanced machines enable precise and productive mechanical processing. The management of the machines is in the hands of highly motivated and trained employees.

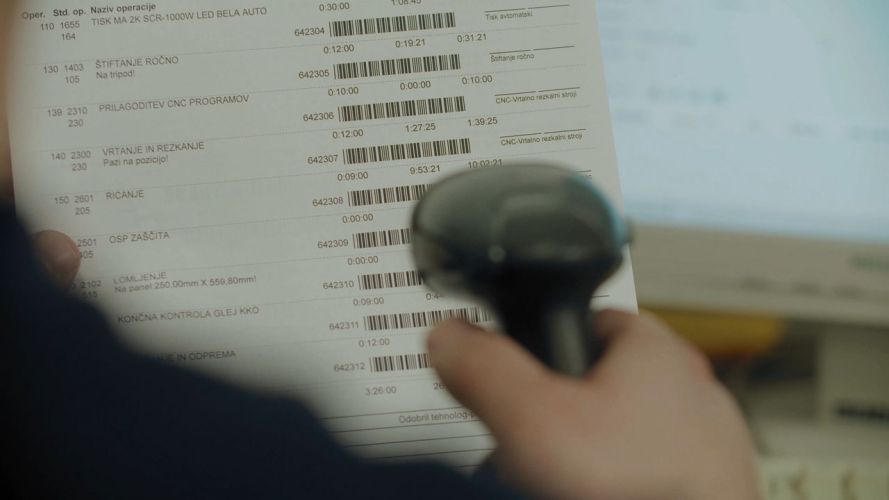

We are distinguished by quality and professionalism. Quality control is not only the concern of the quality department, but of all those involved in the product manufacturing process (from development, to sales, production and shipping). In addition to quality products, we provide a stable, controlled production process or quality in the entire business process, which is also proven by the ISO 9001/2015 certificate.

Only 100% functionally tested products, carefully protected and packed in antistatic packaging, leave our warehouse.

Storage conditions can reduce storage time. High storage humidity may affect the absorption of moisture. We can offer moisture absorbing silica gel and the moisture indicator in the packing to reduce humidity risk.

Our stocks of various CCL materials enable flexible service and a quick response with a lean production line, we adapt to customer requirements, and our printed circuit boards can be delivered in a short time.

For low quantity series of printed circuit boards (up to 100 panels), a special line with exposure process enables us to dispatch within 5 working days, while for larger series of printed circuit boards (up to 2500 production panels), our products can be produced within 15 working days.

Our geographical location enables very short delivery times. The goods travel to the neighbouring countries of Austria, Italy, Germany and Croatia in 1 day and to all other European countries in up to 5 days.