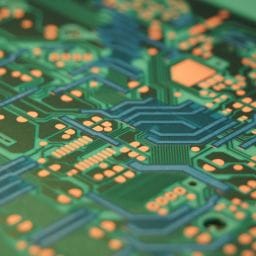

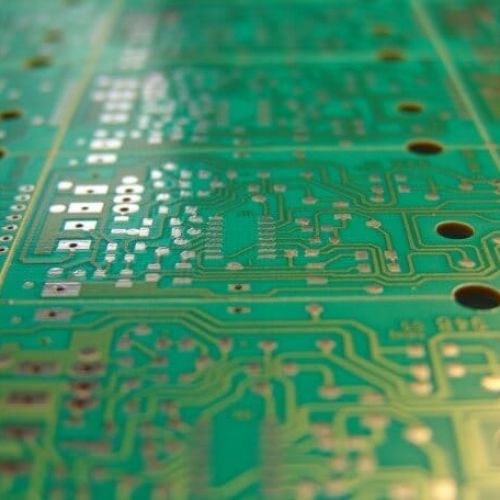

PCB

Today’s car does not exist without PCB. Printed circuit boards can be found in sensors, dashboards, mirrors, various cameras, electronic braking systems, audio systems, driver’s seat control, park systems, door control units, airbag control systems, front and back LED lights etc.

In the near future the cars will run on batteries with all kind of sophisticated electronic equipment and this is the future of automotive PCBs. Electric vehicles will be high-performance with a range of thousands of kilometers, adaptable to severe weather conditions, efficient in high-temperature conductivity, robust with a long service life.

You can find our printed circuit boards in many cars, from the high price range to advanced electric cars and other vehicles.

Electric cars are the future. Car manufacturers are adapting to the growing demand for more environmentally friendly cars. More mass use of electric vehicles will result in reduced greenhouse gas emissions and better air quality in city centers and along the busiest corridors.

The automotive industry is one of the largest industries in the world, consisting of many organisations and companies engaged in the design, development, production and sale of passenger cars and commercial vehicles. Over the years, it has been a fast-growing industry that is gaining new dimensions with the development of new guidelines and electrification. The main products in this industry are passenger cars and light trucks, including pickups, vans and SUVs.

The more than 100-year-old industry, which began in France and Germany and soon developed into mass production in the U.S., became synonymous with the Industrial Revolution in the 20th century.

Today, the car industry is key to the prosperity of the EU. The automotive sector directly and indirectly employs 6.1% of all employees in the EU. The industry is strongly intertwined with other sectors and brings 7% of European GDP.

New cars are becoming more and more complex, requiring more and more electrical parts and many electrical components. New trends, the result of a combination of business model, digital science and new technological materials, have caused the automotive industry to face drastic changes. The automotive industry will transform into a mobile industry in the coming years. The future will bring electric mobility, autonomous vehicles, automatic factories and car sharing.

Printed circuit boards are mainly manufactured for LED lighting technology, household appliances, automotive electronics, telecommunications, medical equipment and other technologies.

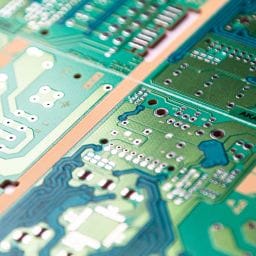

AKA PCB has three production lines designed for serial production and one dedicated line for express PCB service and quick samples production.

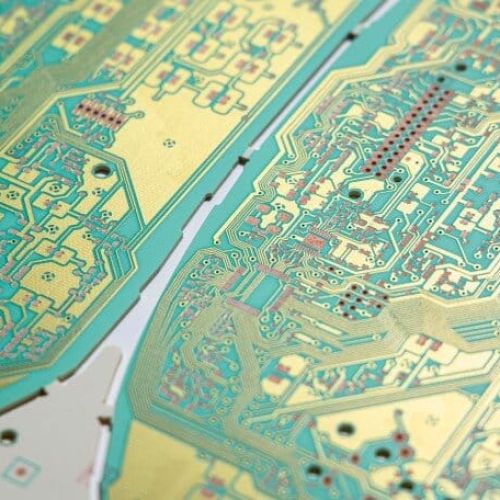

We can process standard panel size 533mm x 610mm, and also double 610mm x 1200mm sheet size.

We process PCB from standard materials in stock:

- FR4 CTI600V

- CEM3 CTI600V

- CEM3 High Thermal CTI600V

- CEM1 CTI600V

- IMS

- special materials.

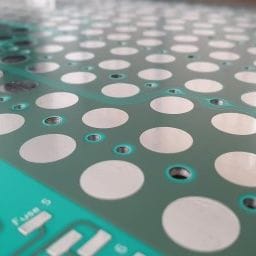

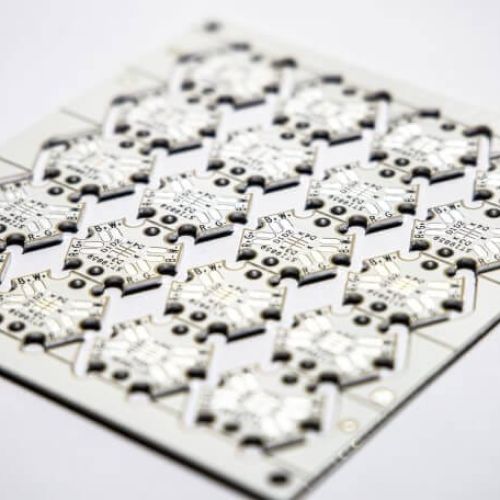

IMS PCBs are used primarily as heat sinks for high power LEDs and other power components.

AKA PCB has three production lines designed for serial production and one dedicated line for express PCB service and quick samples production.

No prepreg type materials:

- 5052 Aluminum Alloy

- Isolation layer 6KV EBD

- Isolation type 2W/MK and above

- Rigid or flex type

- Circuit layer copper thickness 35µm-210µm

- IMS Thermal conductivity 1-9WmK

- CNC or punching processed

- White, black, green or white high reflective solder resists available.

Printed circuit boards mainly used for LED lighting applications (led engines, strips and other applications).

AKA PCB has three production lines designed for serial production and one dedicated line for express PCB service and quick samples production.

We can produce from standard formats to extra-long strips (1200mm x 600mm).

We have in stock all standard PCB LED Engine CCL (copper clad laminates):

- FR4 CTI600V

- CEM3 CTI600V

- CEM3 High Thermal CTI600V

- CEM1 CTI600V

- special materials.

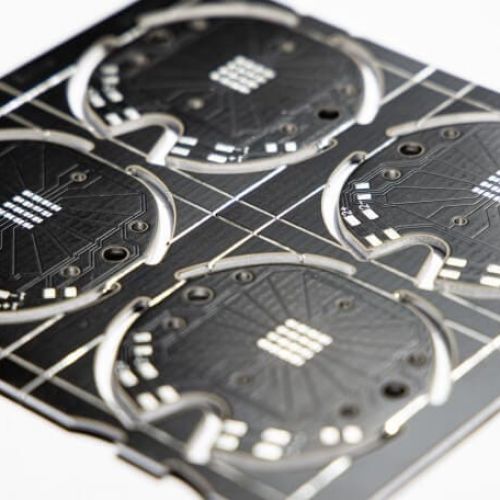

Heavy copper printed circuit boards are designed to use where very high electrical curents are present on board, or in order to dissipate heat away from components.

Printed circuit boards are specially designed for Solar Panels, Power supplies, Automotive industry, power converters and the military.

AKA PCB has three production lines designed for serial production and one dedicated line for express PCB service and quick samples production.

Including:

- FR4 base

- Aluminum base

- Copper base

- Warm white

- Cold white

- High reflection white

- Black

- Green

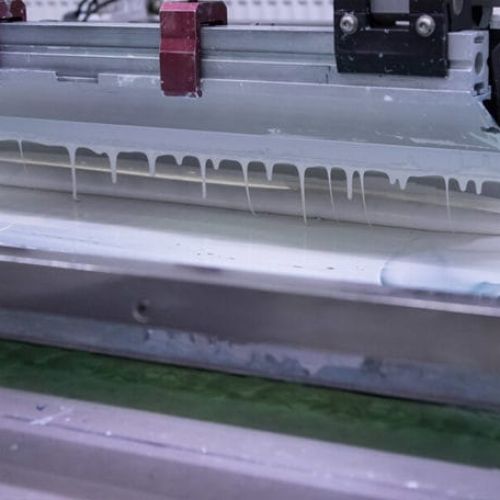

- Exposure process for quick supply and high-resolution projects

- Screen print process for high volume low-cost production

- THERMAL INTERFACE PASTE

- ADHESIVE RESISTANT TO SOLDER PROCESS TEMPERATURE

- SURFACE FINISH – OSP (Organic solder Passivation), HAL (Hot air levelling lead free), ENIG (electroless Nickel immersion Gold)